Cement Ball Mill In India

Ball Mill Promas Engineering Pvt Ltd

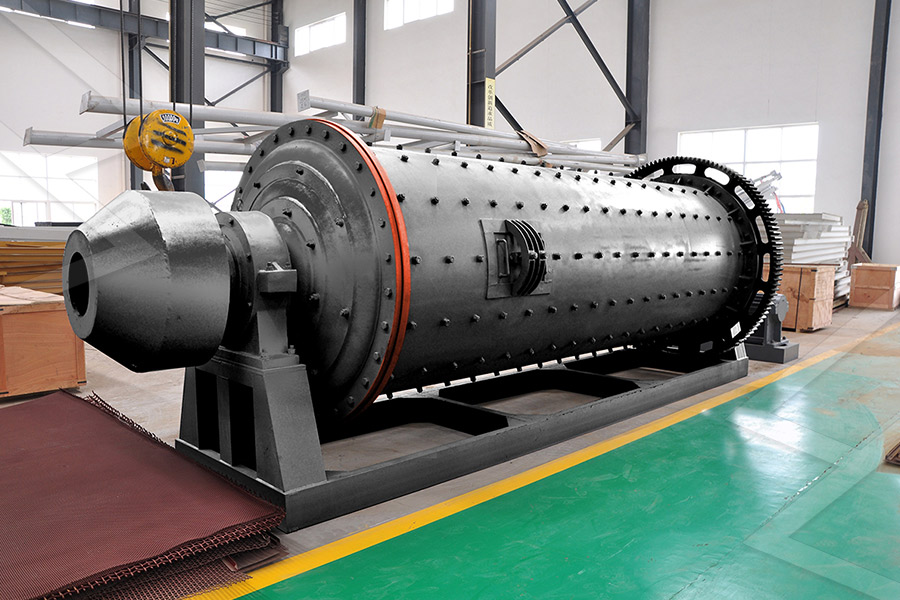

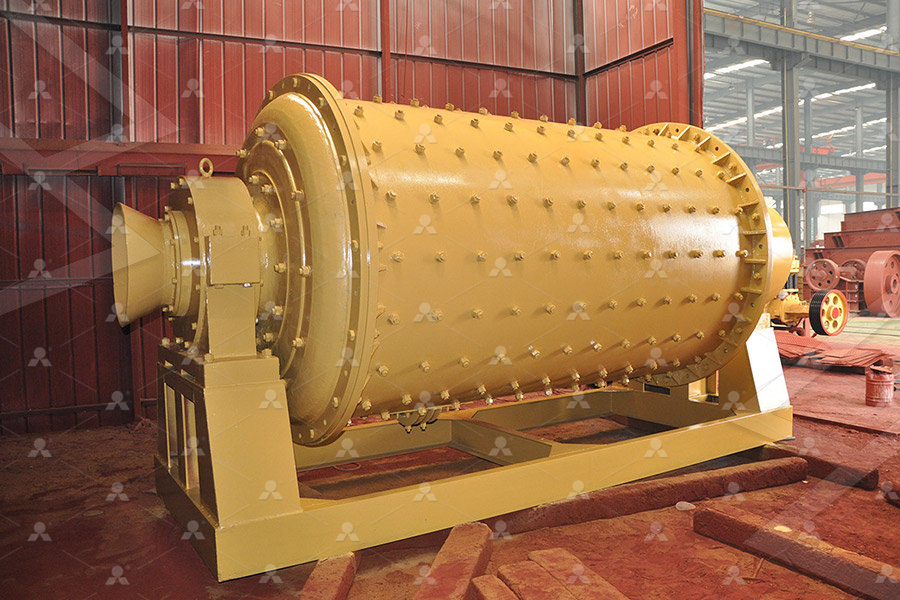

4 天之前 — We are manufacturer, supplier and exporter of ball mills according to ISI guidelines and user’s requirements since 1990 from Mumbai to India and all over the world It is widely used for the cement, the silicate Even in the year of the global pandemic, we have supplied more than 30 ball mills making us the biggest manufacturer and supplier of ball mills in India These numbers are Biggest Manufacturer and Supplier Of Ball Mills In IndiaFind here online price details of companies selling Ball Grinding Mill Get info of suppliers, manufacturers, exporters, traders of Ball Grinding Mill for buying in India IndiaMARTBall Grinding Mill at Best Price in India India Industrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely Ball Mill Manufacturers for Cement Plant in India

.jpg)

Ball Mill Supplier of Ball Mill, Exporter In India

Ball mills are special grinding machineries that are used in the industries for grinding and mixing diverse industrial rawmaterials such as cement, lime stone, asphalt, ores and alloys, chemicals, paint pigments etc We are Promac Engineering Industries Limited is an EPC major, active in the Cement, Power, Steel, and Mineral Processing Sectors We provide turnkey design, engineering, and manufacturing solutions for the Heavy Promac India Engineering ExcellenceWe are manufacturers, providers and exporters of all type of cement plant equipment like Mini Cement Plant Manufacturer, Cement Ball Mills, Rotary kiln plants, clinker plants, Cement Plant ManufacturersWe bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on Closed and Open Circuits Ball Mill for Cement,

Cement plant manufacturers, suppliers

NT Engitech is a trusted name among cement plant manufacturers, suppliers, and exporters in India With a focus on quality and innovation, we offer customized solutions to meet your specific requirements NT Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same Ball Mill In Cement Plant Cement Ball MillIndia’s No 1 Leading Manufacturer Exporter of Ball Mill, Rotary Kiln, Continuous Ball Mill SHALIMAR has a well equipped drawing and design department which finalizes the drawings with high standards of efficiency, performance and safety as wellShalimar Engineering2022年5月23日 — Looking for India's best quality cement manufacturers, producers, exporters, and suppliers: Find more details of the top 10 updated companies dealing in Cement 2022 Manufacturers; Announcement; The feed is finely ground with the primary and secondary chambers of the ball mill There is a set amount of ball charge in each List of Top Largest Cement Manufacturing Companies in India

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 — Same or better strengths than cement from ball mill 251 Cement quality As it was stated in the literature, grinding tests have shown that Cemex® produces cement which meets the requirements of standard specifications while enabling substantial savings in grinding energy consumption compared to the traditional ball mill systems Due to the 2021年1月1日 — The Indian cement industry have many major players in the league The top 20 cement companies produces almost 70% of the total installed production capacity in the country There are 210 large cement plants having total capacity of 410 MT cement production, with 350 small plants account for the rest The cement mill is either a Ball Review on vertical roller mill in cement industry its 2021年4月27日 — Operation and Elements of a ClosedCircuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media andlined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding OPTIMIZATION OF CEMENT GRINDING OPERATION IN Bionics Scientific is a leading laboratory ball mill manufacturers in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive price These machines are supplied with steel Laboratory Ball Mill Manufacturers in india, 5 Kg,10 Kg Price India

Ball Mills Manufacturers Suppliers in India India Business

Find here Ball Mills, Laboratory Grinding Mill manufacturers OEM manufacturers in India Get Contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across IndiaWe Ashoka Group Is a Leading Cement Plant Manufacturers and Cement Plant Machines suppliers, We built high quality cement plants including Rotary Kiln Plants, Clinker Cement Plants and VSK plants We design and manufacture all type of Ball Mill, Vertical Shafts and Silos and all type of Material Handling EquipmentCement Plant Manufacturers2019年1月3日 — Ball mill grinding Evolution of ball mills was the starting point in communition theory adopted widely in cement manufacturing Size reduction process of bulk solids acquires major part of cement process Clinker grinding technology in cement 2024年6月4日 — Energy Benchmarking for Indian Cement Industry 60 List of Tables Table 28 Benchmarking of Cement Mill Section Ball Mill+HPRG PPC 49 Table 29 Benchmarking of Cement Mill Section 53 Table 30 Benchmarking of Packing Section 53 Table 31 Benchmarking of Compressor 54 Table 32 Benchmarking Water Consumption 54 Table ENERGY BENCHMARKING Green Business Centre

.jpg)

Ball Mill (Laboratory Type) at Rs 950000 Ball Mills

Scientific is a leading Ball Mill manufacturer in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 KgIn standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive priceThese machines are supplied with steel grinding balls with 2021年1月6日 — The grinding process of cement in a vertical roller mill over ball mills is optimized by the authors of [21] in order to minimize power consumption The energy consumption is also studied in semi Review on vertical roller mill in cement industry its 2024年2月23日 — The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production How Does a Raw Mill Work in a Cement IndustryManufacturer of Ball Mill Laboratory Ball Mill offered by Standard Scientific Instruments Co, New Delhi, Delhi we offer laboratory ball mill from India Laboratory Ball Mill Get Best Quote Approx Price: Rs 13,000 / Piece The equipment is used in the laboratory to create ground cement samples It is also used in the paint, plastic Ball Mill Laboratory Ball Mill Manufacturer from New Delhi

.jpg)

LOESCHE India Loesche

2024年9月17日 — The first LOESCHE mill supplied in India was for grinding Bentonite material in 1975 to M/sChowgule Industries in Goa However the first LOESCHE mill for cement industry in India was supplied to M/s Dalmia Cement (B) Ltd for their plant in Dalmiapuram Backed with rich design engineering experience of more than 100 years 2021年12月21日 — Subsequent developments like the use of Roller Press and Vertical Mill offers saving of 510 Kwh/t electrical energy consumption for a typical 3200 Blaine cement as compared to a ball mill Ball mill technology has also gone through innovations in terms of various modified impact liners, classifying liners, and flow control diaphragmsRoller press is wellaccepted technology in India Indian Cement 2023年8月23日 — A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement To achieve this crucial transformation, a cement mill What Are the Parts of a Cement Mills? Cement Ball Mill 2024年5月1日 — The growth of the Indian cement sector has been consistent, increasing from 174 million tonnes in 2007 to 329 million tonnes in 2020 Induction motors are widely used in cement plants to operate ball mills, pumps, compressors, sizereduction equipment, etc, and consume significant electrical energy Motors are used in grinding raw materials Analysis of decarbonization measures for the Indian Cement

.jpg)

Ball Mill thyssenkrupp Polysius

The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust After cooling, the clinker is fed into the cement ball mill for grinding The cement ball mill grinds the cement clinker particles to a suitable particle size, forms a certain particle level, increases the hydration area, accelerates 85tph Cement Ball Mill Put Into Operation In Get Laboratory Ball Mill, Capacity: 5Kg 10Kg 15 Kg in New Delhi, Delhi at best price by Aimil Ltd and more manufacturers with contact number ID: Apart from the cement industry, it is also used in the paint, plastic, granite and tile industries The equipment is provided with a revolution counter for recording the revolutions Laboratory Ball Mill, Capacity: 5Kg 10Kg 15 Kg IndiaMARTCoal/Pet Coke Grinding Ball Mill; Clinker/Cement grinding open/close circuit slide shoe/Trunnion bearings ball mills Central Drive Ball Mills with WIL make Central Drive Gear Box; Anjani Portland Cement Ltd in Telangana (India) Article published in International Cement Review Magazine February2014, on ‘’ Grinding on Time with WIL Walchandnagar Industries

.jpg)

JSW Grinding Media, Grinding Balls Manufacturer JSW Steel

2 天之前 — The Grinding Media Mill (GMM) is the first of its kind in India, with a production capacity of one hundred thousand (100,000) tons per year Specification G0ST75242015: Specification for Steel Grinding Balls for Ball Mills DSTU 8538 2015: Steel Milling Balls for Ball Mills Customer Specific Requirement (Customized Products)Get Contact details address of companies manufacturing and supplying Mini Cement Plant across India IndiaMART Get Best Price Shopping Sell Help Messages IndiaMART > Cement and Concrete > Ball Mill Mild Steel Cement Grinding Plant, For Industrial, Capacity: 5 To 150 TPH(100 to 3000 TPD) ₹25,00,000/ Unit Capacity 5 To 150 Mini Cement Plant Manufacturers Suppliers in India2020年5月1日 — In this work, the energy and exergy analyses of a cement ball mill (CBM) were performed and some measurements were carried out in an existing CBM in a cement plant to improve the efficiency of the grinding process The first and second laws efficiency of the CBM was specified to be 805% and 199%, respectively The electrical energy Energy and exergy analyses for a cement ball mill of a new 2012年6月1日 — Mill – Cement and Concrete Research, V ol 33, 2003, 439445 16 D i n g, B C Modern Predictive Control Taylor and Francis Group, 2010 Ball mills can grind a wide range of materials (PDF) Grinding in Ball Mills: Modeling and Process Control

Improvements in New Existing Cement Grinding Mills by

Of the 4 main mill systems in use for cement grinding, ball mills are by far the predominant, despite a higher energy consumption compared with a standalone Vertical Roller Mill or Roller Press; 2 Beside historical reason, ball mills are generally more reliable, simpler to operate maintain, the wear parts readily available stocking cost Highquality mining machinery steel ball mill linerpiyali e Rectangular mill liner plate; Abrasion liner tube; Hardox 600 jaw plate; Hardox 450 jaw crusher plate; Rectangular ms steel liner plate, thickness: 1mm 150mm, Mill Liner plate Manufacturers Suppliers in IndiaIndustrial ball mills made available by us are heavy sheet fabricated using qualityapproved mild steel stainless steel These ball mills are used to grind materials into extremely fine powder Our ball mills are perfect for cement plants Three types of ball Mills we re manufacturing: – 1 Raw materials mill 2 Cement (Clinker) mill 3 Ball Mill Manufacturers for Cement Plant in India2018年12月1日 — Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD productioncement plant equipments manufacturer and suppliers of

Vertical Roller Mill in Cement Plant ball mills supplier

85tph Cement Ball Mill Put Into Operation In Indian Cement Plant Read More Previous slide Next slide Free Material Testing As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for grinding in a variety of industries and 2023年8月12日 — 4 Ball mill for cement grinding Ball mill for cement grinding 5 Outlet grate with adjustable lifters Slide shoe bearing Mill shell with weldedin slide rings and Project Centre India FLSmidth Private Limited FLSmidth House 34, Egatoor, Kelambakkam (Rajiv Gandhi Salai, Chennai) Tamil Nadu – 603 103 Tel: +91444748 1000Ball mill Superior cement quality, More fl exibility, higher 19 Mar 2024; India is a major producer of cement, and the demand for cement clinker grinding ball mill is high There are a number of manufacturers of these mill in India, offering a variety of products to meet the needs of the cement industryCement Clinker Grinding Ball Mill Manufacturers in IndiaIndividual large air swept Vertical Mills are preferred over ball mills for better grinding efficiency and to get an advantage in power consumption Cement raw material is the mixture of mainly Limestone other constituent such Iron oxide, Shale etc having different moisture contain depending on composition depositVRM – AMCL Machinery Limited

.jpg)

MODELING AND SIMULATION OF A CLOSED LOOP BALL

2016年4月11日 — A cement ball mill is a grinder that grinds the clinker to produce fine cement It works on the principle of impact The functioning of ball mill is further India, 20th April 2014, ISBN: 978938 10 II DYNAMICS OF THE BALL MILL GRINDING CIRCUIT product Blaine measured in cm²/g and the rejects Fig1 In a continuous ball Ecorporates GmbH is your single source for supply and procurement of all equipment, spare parts for cement plant We have experience of more than 15 years and understand the operations and requirements of cement factory from quarry to bagging We cover the entire cement industryCement Plant Spares EcorporatesBall Mill Supplier From India We manufacture high performance ball mill in India that are nothing but grinding machineries used to mill and mix materials in the industries such cement industries, glass industries, fertilizer industries, chemical industries, paint industries etc We are leading the ball mill manufacturer, that are made out of the best grade of raw Supplier of Ball Mill Manufacturer and Exporter IndiaWe bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications Classified depending on the circuit design, bearing, grinding type and drive, the selection is made on Closed and Open Circuits Ball Mill for Cement,

.jpg)

Cement plant manufacturers, suppliers

NT Engitech is a trusted name among cement plant manufacturers, suppliers, and exporters in India With a focus on quality and innovation, we offer customized solutions to meet your specific requirements NT Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same Ball Mill In Cement Plant Cement Ball MillIndia’s No 1 Leading Manufacturer Exporter of Ball Mill, Rotary Kiln, Continuous Ball Mill SHALIMAR has a well equipped drawing and design department which finalizes the drawings with high standards of efficiency, performance and safety as wellShalimar Engineering2022年5月23日 — Looking for India's best quality cement manufacturers, producers, exporters, and suppliers: Find more details of the top 10 updated companies dealing in Cement 2022 Manufacturers; Announcement; The feed is finely ground with the primary and secondary chambers of the ball mill There is a set amount of ball charge in each List of Top Largest Cement Manufacturing Companies in India

.jpg)

EnergyEfficient Technologies in Cement Grinding

2016年10月5日 — Same or better strengths than cement from ball mill 251 Cement quality As it was stated in the literature, grinding tests have shown that Cemex® produces cement which meets the requirements of standard specifications while enabling substantial savings in grinding energy consumption compared to the traditional ball mill systems Due to the 2021年1月1日 — The Indian cement industry have many major players in the league The top 20 cement companies produces almost 70% of the total installed production capacity in the country There are 210 large cement plants having total capacity of 410 MT cement production, with 350 small plants account for the rest The cement mill is either a Ball Review on vertical roller mill in cement industry its 2021年4月27日 — Operation and Elements of a ClosedCircuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media andlined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding OPTIMIZATION OF CEMENT GRINDING OPERATION IN Bionics Scientific is a leading laboratory ball mill manufacturers in India and offers its customers a fair deal in buying ball mills with facilities of customized size and capacities up to 10 Kg In standard, these lab scale ball mill machines come in 2Kg, 5Kg and 10 Kg and are sold all over India at highly competitive price These machines are supplied with steel Laboratory Ball Mill Manufacturers in india, 5 Kg,10 Kg Price India

Ball Mills Manufacturers Suppliers in India India Business

Find here Ball Mills, Laboratory Grinding Mill manufacturers OEM manufacturers in India Get Contact details address of companies manufacturing and supplying Ball Mills, Laboratory Grinding Mill, Large Roll Ball Mill across India