Instalation Of Jaw Crusher Mechine

.jpg)

Jaw crushr operate manual: how to install, repair

2024年9月18日 — 1 Preparation of jaw crush foundation Jaw crushers are usually installed on concrete foundations, with a drainage trough reserved for the foundation, preferably with a slope of less than 50 degrees Due This article will explain in detail the installation and use of the jaw crusher What is the jaw crusher for? The jaw crusher belongs to primary and secondary crushing equipment in the mining industry and plays a vital How To Install And Use Jaw Crusher Properly?2021年3月10日 — Installation Ensure that the support structure is capable of safely supporting the weight of the crusher The crusher should be positioned to allow safe, LMC50 JAW CRUSHER USER MANUAL LaarmannThe skills and notes of the installation of jaw crusher, the parts how to install, such as frame, shaft and bearing, connecting rod, toggle plateInstallation of Jaw Crusher Skills and Notes

.jpg)

jaw crusher 百度百科

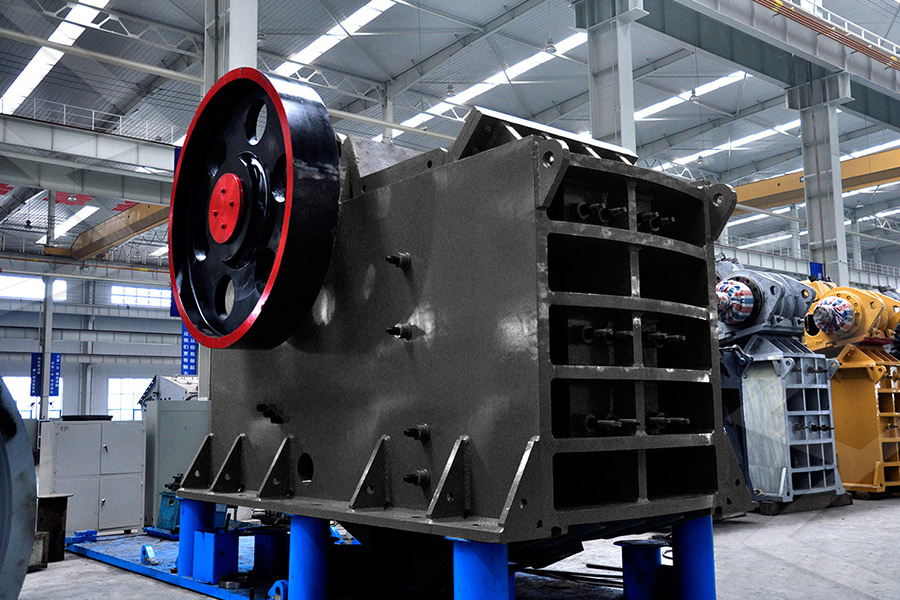

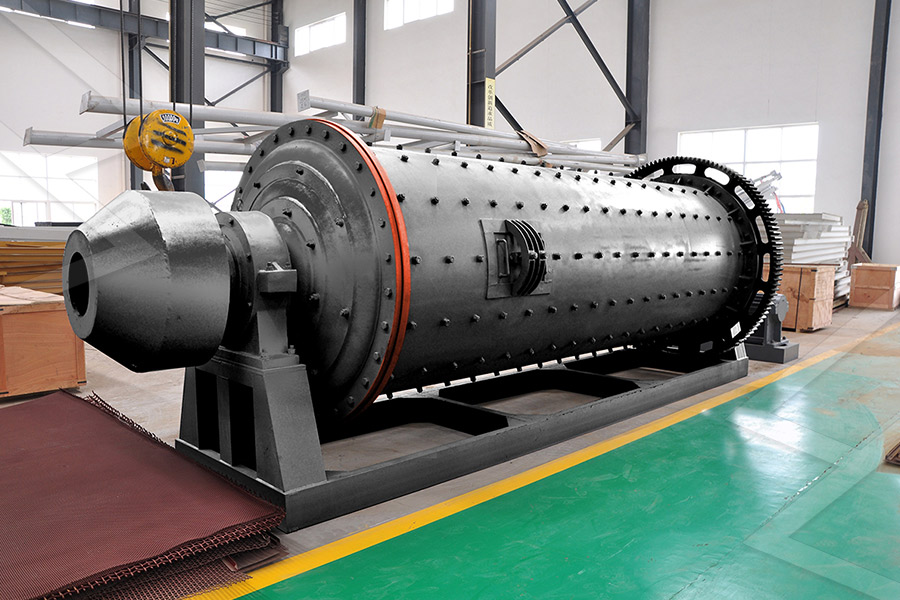

Jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the movable jaw plate move by a regulated track Therefore, the materials in 2024年7月12日 — The jaw crusher should be installed on a concrete foundation, and in order to reduce vibration, wooden or rubber pads should be added between the foundation and Installation, operation and maintenance of jaw crusher2023年2月21日 — A jaw crushing machine is a type of equipment used to break down hard materials, such as rocks, minerals, and ores It consists of a fixed jaw plate and a movable jaw plate that is positioned in a V The Ultimate Guide to Jaw Crushing Machines: 2013年5月20日 — JCE系列欧版颚式破碎机常被用于粗、中碎作业,是颚式破碎机系列中的高端产品。 该设备集结了世界上最先进的技术和加工工艺,在结构设计、工作性能、使用寿命 JCE系列欧版颚式破碎机 JCE Series Jaw Crusher SKJ

.jpg)

Installation, operation and maintenance of jaw crusher

2024年7月12日 — The jaw crusher should be installed on a concrete foundation, and in order to reduce vibration, wooden or rubber pads should be added between the foundation and 2016年1月18日 — The reduction ratio is driven by the Crusher Close Side Setting The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the Crusher Close Side Settings 911Metallurgist2024年9月28日 — Today, this pioneer crusher is the standard for all jaw crushers Types Of Crusher Machines There are various types of stone crushers Each is different in crushing application depending on the material to be destroyed, the desired product size, the feed size, and the crusher’s capacity Still, below are some common types of crusher machinesCrusher Machines: 10 Types to Know Komplet America2022年2月22日 — A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top Jaw Crusher: Range, Working Principle,

Types of Crushers: What You Need to Know Machinery

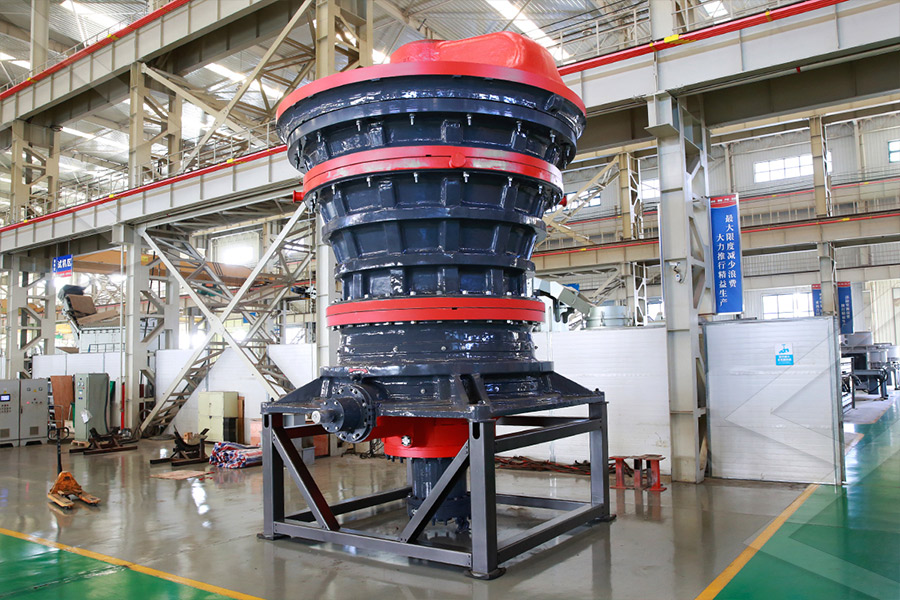

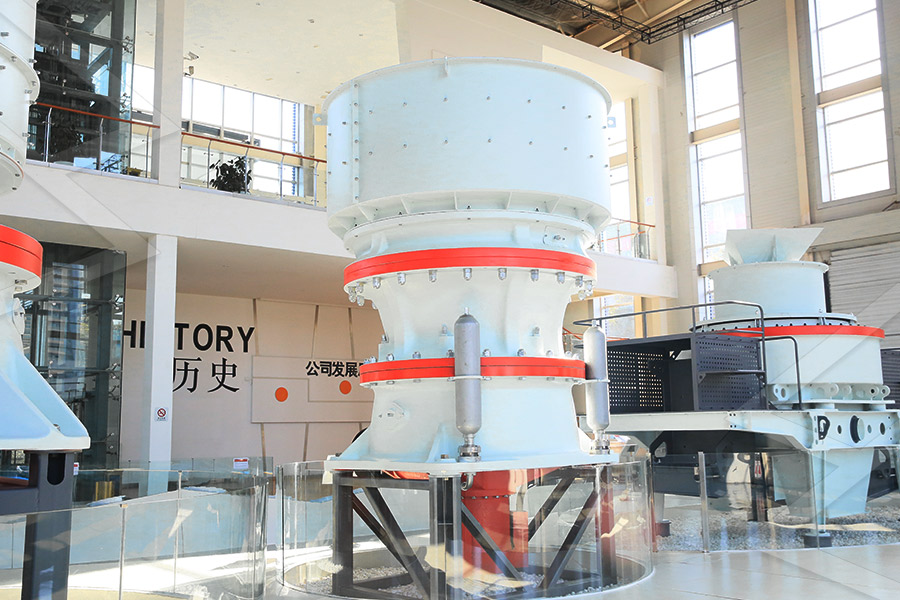

This is because the Blake Jaw Crusher integrated a key mechanical principle – the toggle linkage – a concept students of mechanics are familiar with In 1881, Philetus W Gates received a US patent for his device featuring the basic ideas of today’s gyratory crushers In 1883 Mr Blake challenged Mr Gates to crush 9 cubic yards of A Jaw Crusher is fully mobile, single toggle crusher ideal for crushing in primary or secondary applications, including the reduction of runofmine ore, blasted rock, river gravel, and demolition or recycled concrete Recommended ForCrusher Hire Cone Crusher Hire Jaw Crusher Hire Renico instalation of jaw crusher mechine Home Page Back Mobile Jaw Crusher is designed more reasonable and compact, including installation in broken machine bracket Shang of broken machine, 31 Jaw crusher; 32 Gyratory crusher; 33 Cone crusher 331 Compound cone crusher; Jaw crushers are heavy duty machines and hence need to instalation of jaw crusher mechine hebergementvosges2017年4月18日 — The quality products manufactured by Tech Makkers is Jaw Crusher, Portable Crushing Unit, Cone Crusher, Vertical Shaft Impactor, Vibrating Screen Tech Makkers offers jaw crushers, which are designed for consistent in performance in all type of heavyduty applications Tech Makkers began as a pioneer brand in the field of crushing Jaw Crusher Manufacturer, Jaw Crusher India, Crushing

HSN Code for Jaw Crusher in India Export Genius

HSN Code Product Description; 8474: Machinery for sorting, screening, separating, washing, crushing, grinding, mixing or kneading earth, stone, ores or other mineral substances, in solid (including powder or paste) form; machinery for agglomerating, shaping or moulding solid mineral fuels, ceramic paste, unhardened cements, plastering materials Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements Desired crushing takes place when fed particles experience stress and the compressive pressure exerted by the jaw blade toggling action exceeds its fracture stress By this action the feed particles are crushed to smaller sizesEfficient Jaw Crusher for Coal Analysis Insmart SystemsThe crushing performance of a jaw crusher depends on the operational sloped angle of the jaws (1) and the ir shape, the speed and the movement behavior of the fourbar linkage During one revolution of the fourbar linkage, the breaking jaw moves in vertical and Retsch : 产品 : 粉碎设备 : 颚式粉碎仪2024年9月26日 — But many people don’t know that jaw crushers come in all shapes and sizes, from small tabletop models to massive industrial machines So what exactly is a jaw crusher, and how does it work? What Jaw Crusher: What Is It How Does It Work?

Sand Crusher Machine at Best Price in India

Arihant horizontal shaft impact crusher, capacity: 25 tph, m Cast iron hsi m sand crusher machine, capacity: 45 ton per h Wet mix macadam, capacity: 7,9 units; Rd highchrome steel vsi crusher machine, capacity: 50tph 2024年9月27日 — Incorporating a Terex® Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the Finlay® J1175 gives optimum production in a range of applications Its compact size, quick set up J1175 Tracked Jaw Crusher Rock Crushing The powerful jaw crusher is capable of a variety of tasks with its large underbelt clearances, and is equipped with a hydraulic raise and lower facility on the main conveyor as standard There are a number of features to minimize operator intervention whilst maximizing their safety, such as the selflocking hopper and jaw level sensor which Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher 2023年2月28日 — Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore The Importance of Jaw Crusher Design Features in Crushing

.jpg)

Jaw Crusher MadeinChina

The Jaw Crusher is a premium choice in the Mining Crusher categoryMining crushers are commonly crafted using materials such as steel, cast iron, and aluminum alloys due to their durability and strength The selection of material typically depends on the intended application and the degree of abrasion or compression involvedFind here Jaw Crusher, Heavy Duty Jaw Crusher manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Jaw Crusher, Heavy Duty Jaw Crusher across IndiaJaw Crusher Heavy Duty Jaw Crusher Latest Price, 2 Both the structure and working of a jaw crusher are quite simple 3 The product size is quite small and can range up to millimetres 4 Repair and maintenance of a jaw crusher are convenient and easy 5 The reliability of a jaw crusher is significantly high 6 The broken parts of the jaw crusher are easy to replace Disadvantages of a Jaw Jaw Crusher Working Principle StudiousGuyJaw crusher In crushing and processing lines, jaw crushers are typically utilized as primary crushers The function of a crusher is to reduce large rocks and minerals to smaller pieces Jaw crushers made by TFI Company have a wide range of uses in the crushing of hard materials such iron ore, copper ore, lead and zinc, quartz, feldspar, etcJaw crusher – Industrial Metalworking Machines – UAE

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 — The hydraulic jaw crusher is ideal for crushing hard and abrasive materials, and it is commonly used in mining, metallurgy, building materials, and chemical industries One of the advantages of a hydraulic jaw crusher is its ability to adjust the discharge opening easily, allowing for a wider range of output sizes 2020年3月19日 — Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers Selecting the right crusher for your operations2023年2月15日 — a template of jaw crusher checklist 2Do the lubrication job well The lubrication of the interface between the parts of the jaw crusher is very important It can minimize the friction generated during the The Most Practical Jaw Crusher Repair and 2021年1月30日 — Abstract The vibrations of a vibrating jaw crusher model, excited by two selfsynchronizing unbalancedmass vibration exciters, with allowance for the interaction with the processed medium are examined It is found that the frequency range of stable antiphase synchronization of the exciter rotation required for normal operation of the SelfSynchronization of a Vibrating Jaw Crusher with

.jpg)

BICO CHIPMUNK JAW CRUSHER TYPE WD

2007年3月19日 — Bico, Inc 3116 Valhalla Drive, Burbank, CA 91505 Tel (818) 8427179 – Fax (818) 8427976 sales@bicoinc INSTALLATION Unpack your Crusher and set it on a platform in the desired location2023年2月23日 — Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries These machines are designed to crush large rocks and ores into smaller pieces for further processing A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the Understanding Jaw Crusher Parts and Their Functions AGICOk750 jaw crusher:hooklift jaw crusher The K750 combines superior crushing performance with the ability to transport with a standard hook lift truck From unloading to operating in less than 5 minutes, the K750 jaw harnesses the power of the onboard Diesel electric generator to crush 0400mm rock, concrete and brick at typically 50100tphJaw Crushers — NordmannJaw crusher tooth plate is directly used for crushing ore parts Its structure is simple, but because of frequent contact with the ore, tooth plate is the crusher wear quickly So it is often needed to replace the parts There are two kinds of crosssection structures shape of the tooth plate, the smooth surface and the lattice surfaceInstallation of Jaw Crusher Skills and Notes JXSC Mine

Jaw Crusher Explained saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionThe optimization aim is to reduce characteristic value of moving jaw plate, to raise capacity of jaw crusher, and to ensure entrance and outlet dimensions of jaw crusher Firstly, formulae are derived for displacement of the topmost point and the bottommost point of moving jaw plate, and for the meshing angle between moving jaw plate and fixed jaw plateOptimization Design for Crushing Mechanism of Double 2017年8月27日 — jaw crusher Concrete floor G7 G4 Fig 1Building housing primarycrushing unit a) section; b) foundation of SMD60A jaw crusher; c) settlement curves of column foundations in axes G4 and G7 Dynamic load Indicators harmonic pulse Peak force, kN horizontal vertical 116 138 3500Frequency of force effect, Hz 208 60 Distance Vibration Insulation for Jaw Crushers ― an Effective 2021年5月6日 — A sectional view of the singletoggle type of jaw crusher is shown below In one respect, the working principle and application of this machine are similar: the movable jaw has its maximum movement at the Jaw Crusher Working Principle 911Metallurgist

Below the surface: Setting up an underground

2014年4月1日 — Then lay the pitman from the jaw crusher on its side to work on bearings or place the gyratory main shaft upright When the hole is not in use, it must be covered Preventative and predictive maintenance is 2023年2月15日 — The Dodge jaw crusher has a variable feed area and a fixed discharge area, which leads to choking of the crusher and is not ideal for hard materials Construction and Design: The Blake jaw crusher A Guide to Types of Jaw Crushers for Crushing As a top crusher manufacturer, Propel machines efficiently compress and break rocks, ensuring peak crushing efficiency at the lowest cost per ton JAW CRUSHERS Propel AVJ series single toggle Jaw Crusher offers maximum possible fatigue strength and best reliability with various mounting possibilities The fullywelded sturdyCrusher Machine Manufacturer Propel Industries Coimbatore2024年7月30日 — Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" “Computer Aided Design of Jaw crusher” 911 Metallurgist

Investigation of the jaw crusher operation with backlash eliminators

2021年7月1日 — The condition for the appearance of additional dynamic forces in the presence of gaps in the journal bearings of the jaw crusher is determined The design of the backlash eliminator equipped with pneumatics is described It was experimentally established that the use of pneumatic devices for backlash elimination in the interfaces of 2024年9月26日 — The MAGNA MT120J is a highperformance jaw crusher plant, perfect for robust applications where precision and reliability are paramount For even larger demands, the MAGNA MT130J is our largest tracked jaw crusher, specifically developed for extensive quarry and mining operations, delivering superior crushing power and outputJaw Crushers MAGNA LargeScale Quarrying Machinery4 天之前 — A jaw crusher is the most commonly used primary crusher It uses simple technology to break down large blocks into smaller pieces Their simplicity requires little engineering expertise to operate A jaw crusher is reliable and needs less maintenance than other types of crushers A jaw crusher has one fixed and one moving surface in a V Buyer’s Guide: Crushers Equipment Contracting2023年9月30日 — The jaw crusher angle and rotating mass type are considered to study all particle sizes and reduction ratios obtained for three different motor operation speeds: 1500, 2000, and 2500 rpm Coarse Investigation of vibrating jaw crusher experimental variables

What Are Jaw Crushers and How Do They Work? Oreflow

The singletoggle jaw crusher has less shafts and bearings compared to doubletoggle jaw crushers Only one toggle goes from the bottom of the swinging jaw back to the fixed point Doubletoggle jaw crushers In a doubletoggle jaw crusher, the moving crusher jaw is driven by the eccentric shaft that moves the front and rear toggles up and down2016年1月18日 — The reduction ratio is driven by the Crusher Close Side Setting The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the Crusher Close Side Settings 911Metallurgist2024年9月28日 — Today, this pioneer crusher is the standard for all jaw crushers Types Of Crusher Machines There are various types of stone crushers Each is different in crushing application depending on the material to be destroyed, the desired product size, the feed size, and the crusher’s capacity Still, below are some common types of crusher machinesCrusher Machines: 10 Types to Know Komplet America2022年2月22日 — A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism The jaws are farther apart at the top Jaw Crusher: Range, Working Principle,

Types of Crushers: What You Need to Know Machinery

This is because the Blake Jaw Crusher integrated a key mechanical principle – the toggle linkage – a concept students of mechanics are familiar with In 1881, Philetus W Gates received a US patent for his device featuring the basic ideas of today’s gyratory crushers In 1883 Mr Blake challenged Mr Gates to crush 9 cubic yards of A Jaw Crusher is fully mobile, single toggle crusher ideal for crushing in primary or secondary applications, including the reduction of runofmine ore, blasted rock, river gravel, and demolition or recycled concrete Recommended ForCrusher Hire Cone Crusher Hire Jaw Crusher Hire Renico instalation of jaw crusher mechine Home Page Back Mobile Jaw Crusher is designed more reasonable and compact, including installation in broken machine bracket Shang of broken machine, 31 Jaw crusher; 32 Gyratory crusher; 33 Cone crusher 331 Compound cone crusher; Jaw crushers are heavy duty machines and hence need to instalation of jaw crusher mechine hebergementvosges2017年4月18日 — The quality products manufactured by Tech Makkers is Jaw Crusher, Portable Crushing Unit, Cone Crusher, Vertical Shaft Impactor, Vibrating Screen Tech Makkers offers jaw crushers, which are designed for consistent in performance in all type of heavyduty applications Tech Makkers began as a pioneer brand in the field of crushing Jaw Crusher Manufacturer, Jaw Crusher India, Crushing

.jpg)

HSN Code for Jaw Crusher in India Export Genius

HSN Code Product Description; 8474: Machinery for sorting, screening, separating, washing, crushing, grinding, mixing or kneading earth, stone, ores or other mineral substances, in solid (including powder or paste) form; machinery for agglomerating, shaping or moulding solid mineral fuels, ceramic paste, unhardened cements, plastering materials Jaw Crusher is a basic sample preparation unit and is essential to address all primary size reduction requirements Desired crushing takes place when fed particles experience stress and the compressive pressure exerted by the jaw blade toggling action exceeds its fracture stress By this action the feed particles are crushed to smaller sizesEfficient Jaw Crusher for Coal Analysis Insmart SystemsThe crushing performance of a jaw crusher depends on the operational sloped angle of the jaws (1) and the ir shape, the speed and the movement behavior of the fourbar linkage During one revolution of the fourbar linkage, the breaking jaw moves in vertical and Retsch : 产品 : 粉碎设备 : 颚式粉碎仪